Configuration

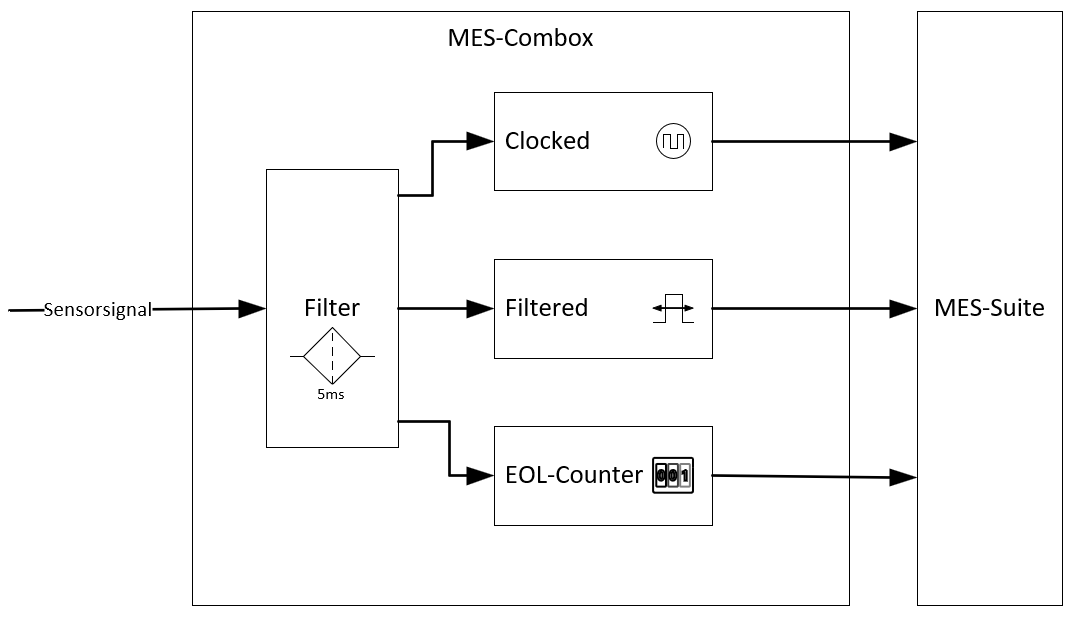

All input signals are first filtered in the MES-Combox. Input signals shorter than 5ms are ignored to prevent false information due to flickering of the sensor. This filter time can be adapted to special conditions by the MES-Suite-Support if necessary. The signal filtered in this way can then be configured and evaluated via the following functions for the MES-Suite:

- Clocked 500: Depending on the cycle time, the MES-Suite cannot process the sensor signals in the cycle time in which they are generated. Especially cycle times below 0.5s can lead to problems. The function Clocked 500 first collects the incoming sensor signals in a memory and then forwards them in a fixed clock suitable for the MES-Suite. If a signal is to be counted that is continuously generated at a high frequency during the operating period, this function is rather unsuitable, since the backlog in the memory continues to grow over time and cannot be processed.

A typical application for this function would be, for example, a light grid that counts NOK parts falling through a light grid.

Since frequency and signal length are static, a cycle time analysis is not possible with the signals which are evaluated via this function. - Filtered: This function forwards the filtered signals 1:1, that means with the same frequency and duration as they are generated by the sensor, to the MES suite. Depending on the application, cycle times can be recorded in this way, for example.

An example of this function would be to determine the process time of a saw by interrogating the sensor of the clamping jaws. - EOL (Amount + Trigger): The EOL function is used to count sensor signals which are generated continuously at high frequency. The sensor signal must be integrated twice in the MES-Suite, once as Amount variable and once as Trigger variable. For the Trigger variable it is checked every 5s whether the counter of the associated sensor signal in the EOL counter has a value > 0. If this is the case, this value is written into the Amount variable and the counter is reset. Then the value of the Amount variable is transferred to the MES suite. This means that signals which are generated during the transmission to the MES suite are included in the sum of the following transmission.

A classic application for this would be an eccentric press, for example.