(remove this paragraph once the translation is finished)

End-of-Line (EOL)

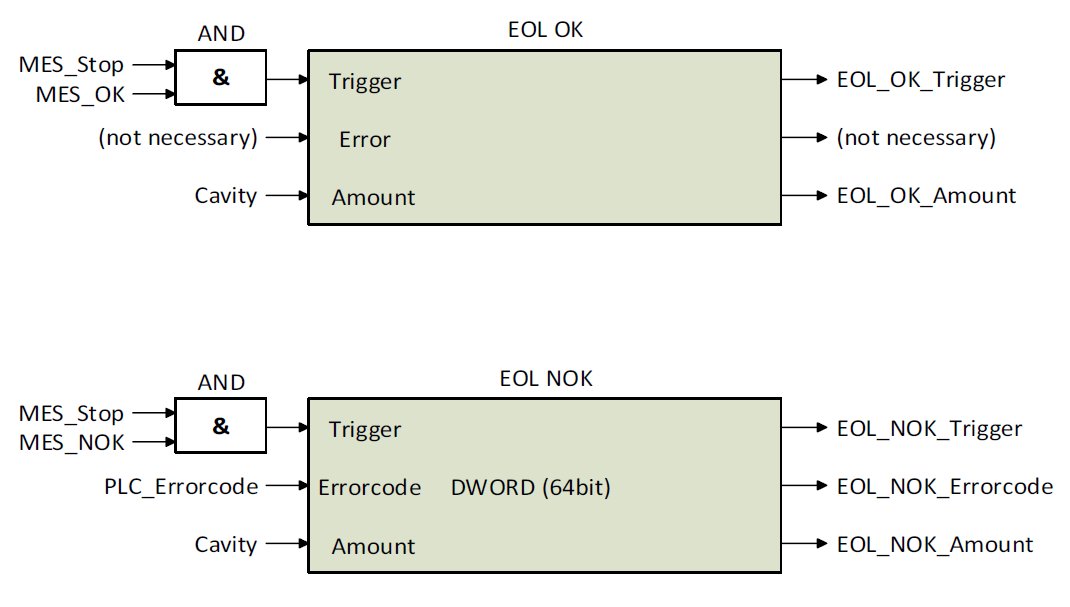

In most cases, a work center has at least two exit points: One for parts that are OK and one for parts that are NOK. If a function can eject a part as OK or NOK, it has to be configured as an exit point.

| Variable | Type | Description | Direction | |

|---|---|---|---|---|

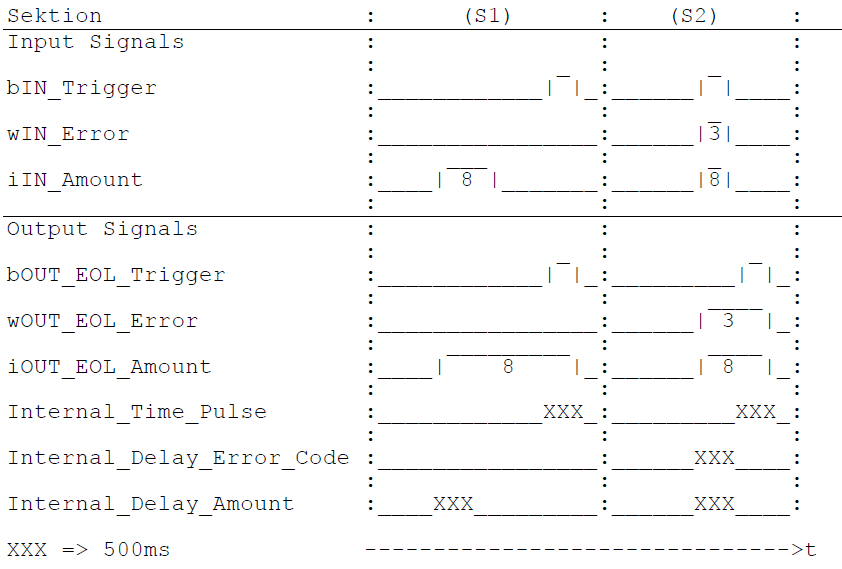

| Trigger | BOOL | Signals the exit point of a product from a work center. It can be parts that are OK or NOK. With rising edge all information of the alarm code and amount variables have to be available. | From PLC to MES | |

| Alarm code | BOOL | Represents the cause of an error (error code). Only for parts that are NOK. | From PLC to MES | |

| Alarm codes | BOOL/BYTE/WORD/DWORD/UINT/UDINT | Bitwise error reasons that represent an error reason (error code) with each bit. Only for parts that are NOK. | From PLC to MES | |

| Amount | INT/UINT/UDINT | If several parts are involved, the quantity has to be specified with an integer number. If the variable is not assigned, the standard value is 1. | From PLC to MES |

Several error code variables can be processed with one trigger. Several parallel error codes are also possible. If the number is greater than 1, the error code is adopted equally for all parts.