(remove this paragraph once the translation is finished)

Process time

Each function is mapped by its own step chain in the PLC. If this contains a waiting time at the beginning or end, this waiting time should be excluded. The MES-Suite receives the process time start or end signal before or after the waiting time. Only the time actually needed to do something with the product is the process time.

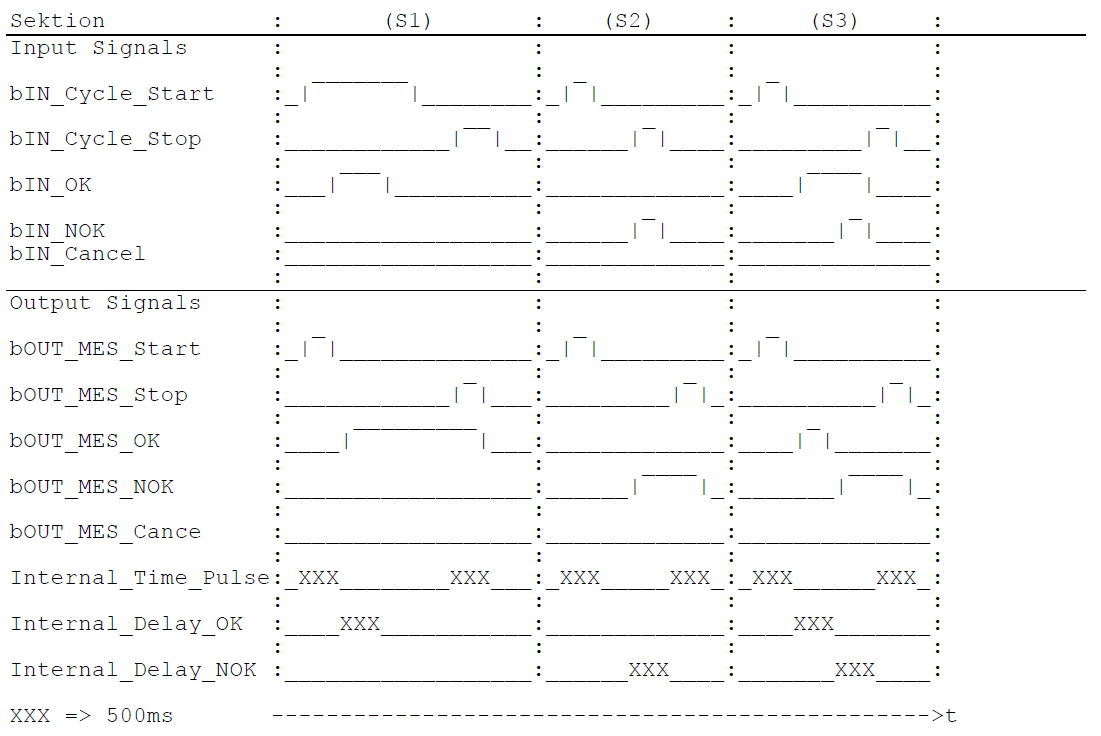

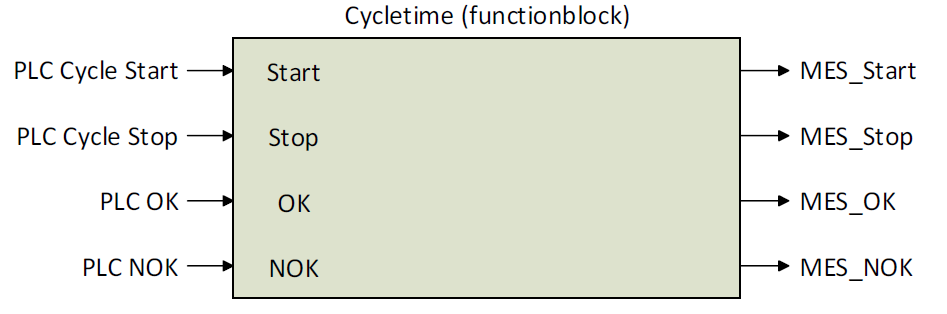

With a start and stop variable

With a rising edge of the start variable (BOOL) the time measurement of the function is started. With a rising edge of the stop variable (BOOL), the time elapsed until then is measured - the cycle time.

With a single variable

With rising edge of the variable (BOOL) the time measurement of the function is started. At falling edge the past time is measured - the cycle time.

Material

The processed product can be passed as a variable (STRING). This can be, for example, the name of the currently selected recipe.

IO/NIO Bool

If a cycle is completed, it can be decided whether the processed parts are marked OK or NOK. For redundancy reasons, two separate BOOL variables are used: OK and NOK. The number of processed parts per cycle is specified by an additional variable (any integer type can be used). The OK/NOK variables must receive their value before the signal indicating the end of the cycle is present.

IO/NIO UDINT

If a function can indicate how many of the processed parts were OK/NOK in a cycle, the quantities can also be passed directly instead of the Boolean method. Two variables (OK and NOK each as UDINT) are required for this. These must have received their values before the variable is switched to stop.