(remove this paragraph once the translation is finished)

Variant "Read" a) Read product data (basis product ID)

| Variable | Data type | Description | Direction | |

|---|---|---|---|---|

| Read* | BOOL | This variable sets PLC when new data is available and PLC sets it back to FALSE | From PLC to MES | |

| Read* | BOOL | This variable describes MES with TRUE, if the data was stored in the database. MES resets it to FALSE | From MES to PLC | |

| Product ID* | STRING | The generated database GUID is passed from PLC to MES, so that the measured values can be assigned faster | From PLC to MES | |

| Product Code* | STRING | The generated product code is provided by MES to PLC | From MES to PLC | |

| Product* | STRING | The product is provided by MES to the PLC | From MES to PLC | |

| Measured value 1..N | miscellaneous | The measured values or states of the produced part can be evaluated by the PLC in various data formats | From MES to PLC |

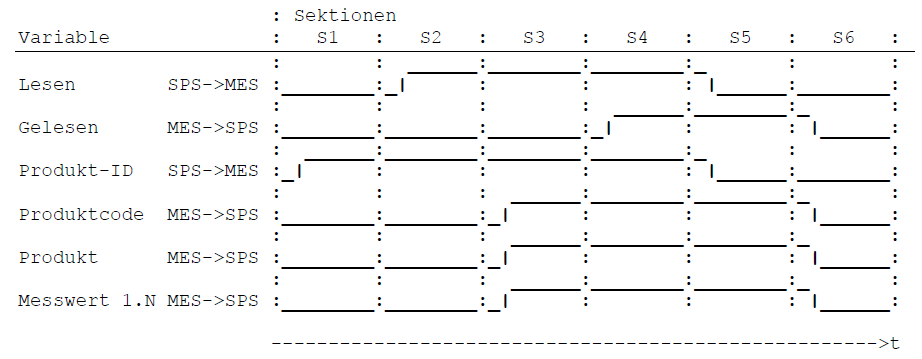

- Section 1:

- {Product ID} is set by PLC at least 300ms before {Read}.

- Section 2:

- {Read} is set by PLC

- Section 3:

- {product code} is set by MES

- {Product} is set by MES

- {measured values 1..N} are optionally set by MES

- Section 4:

- {Read} is set by MES.

- Section 5:

- {Read} is reset by PLC (Reason: rising edge {Read}).

- {Product ID} is reset by PLC (Reason: rising edge {Read}).

- Section 6:

- {Read} is reset by MES (Reason: falling edge of {Read})

- {Product code} is reset by MES (Reason: falling edge of {Read})

- {Product} is reset by MES (Reason: falling edge of {Read})

- {Measured values 1..N } are reset by MES (Reason: falling edge of {Read})