(remove this paragraph once the translation is finished)

PDA

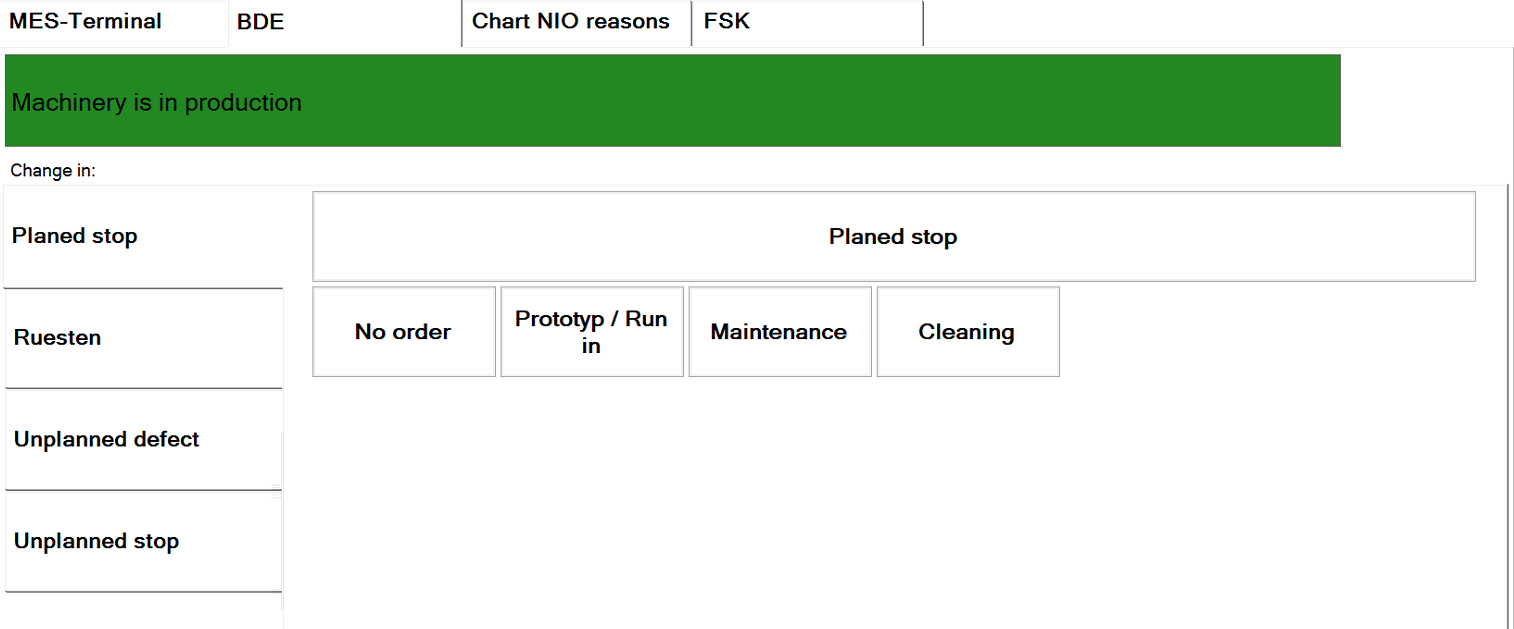

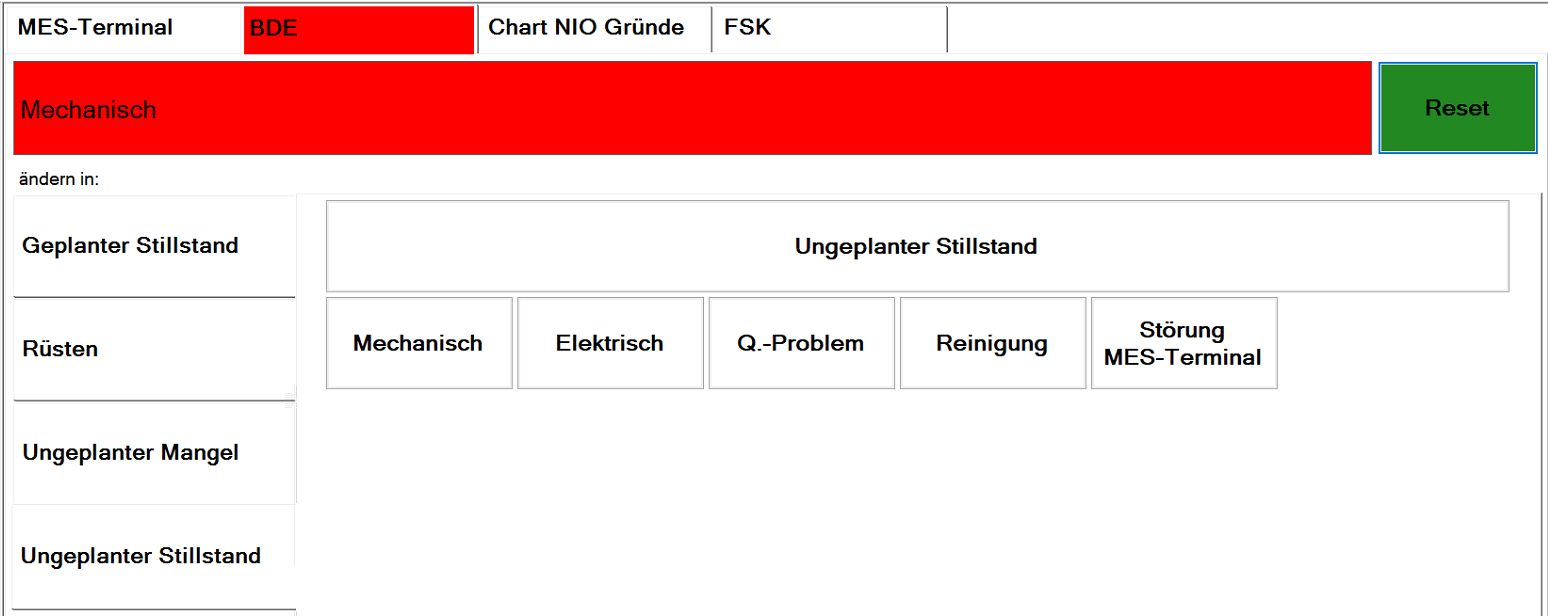

Under PDA the technical operating modes of a plant are recorded, which cannot be recorded automatically by the machine control. The first line shows the current status (here Plant is in production). If a status other than Plant is in production is set, there is a Reset button next to the status display, which can be used to set the status back to Plant is in production again. The times and reasons for a plant shutdown are recorded via the statuses defined here. Under the plant status are the four options

- planned downtime,

- Set-up,

- Unplanned shortage, as well as

- Unplanned downtime,

where the active plant status can be activated.

The plant status Plant is in production does not mean that the plant is actually producing something, but only that none of the other reasons (see below) are present that would prevent production. The plant is therefore ready for operation from the point of view of the MES terminal.

Theoretically, the PDC status can be set independently of the plant status. For example, the plant could be producing for a planned order while the PDC status unplanned shortage is set. This should be avoided at all costs, as this generates contradictory data.

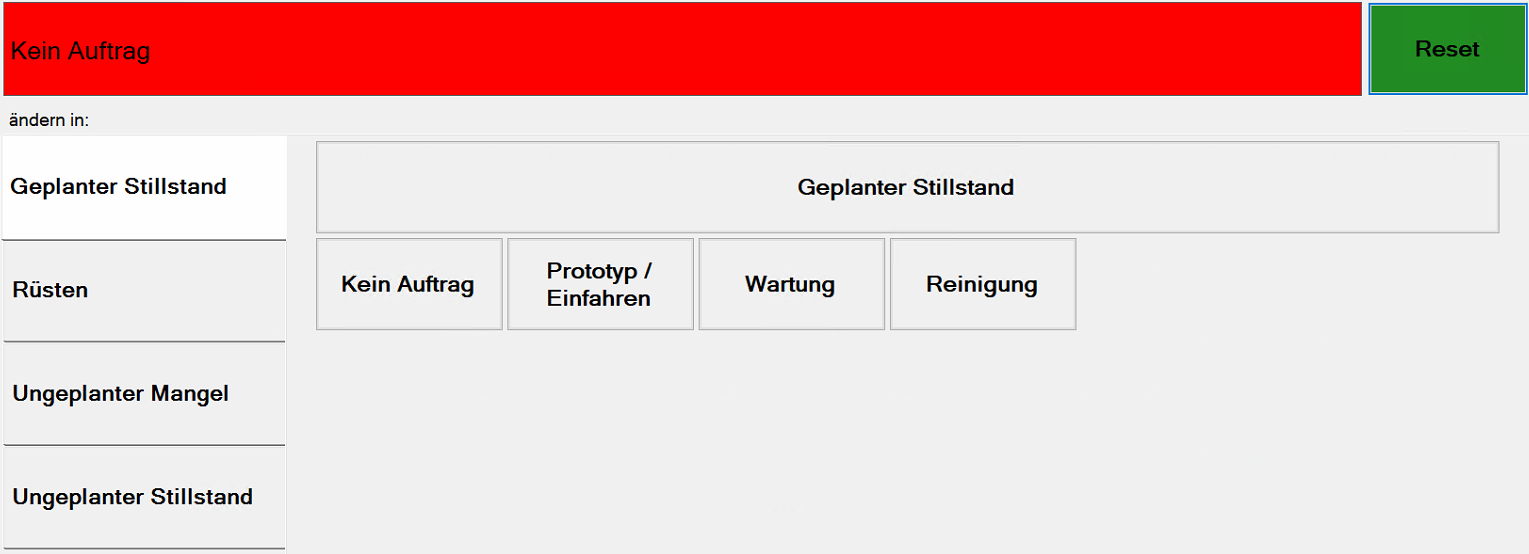

Planed Downtime

Under the menu item Planned downtime the following reasons can be defined for the plant not currently being in production:

- No order: No production is possible because there are no orders.

- Prototype/Run-in: The plant is currently being operated as scheduled for test purposes and therefore cannot produce components for regular orders.

- Maintenance: Scheduled maintenance is being performed on the plant.

- Cleaning: The plant needs to be cleaned on a scheduled basis.

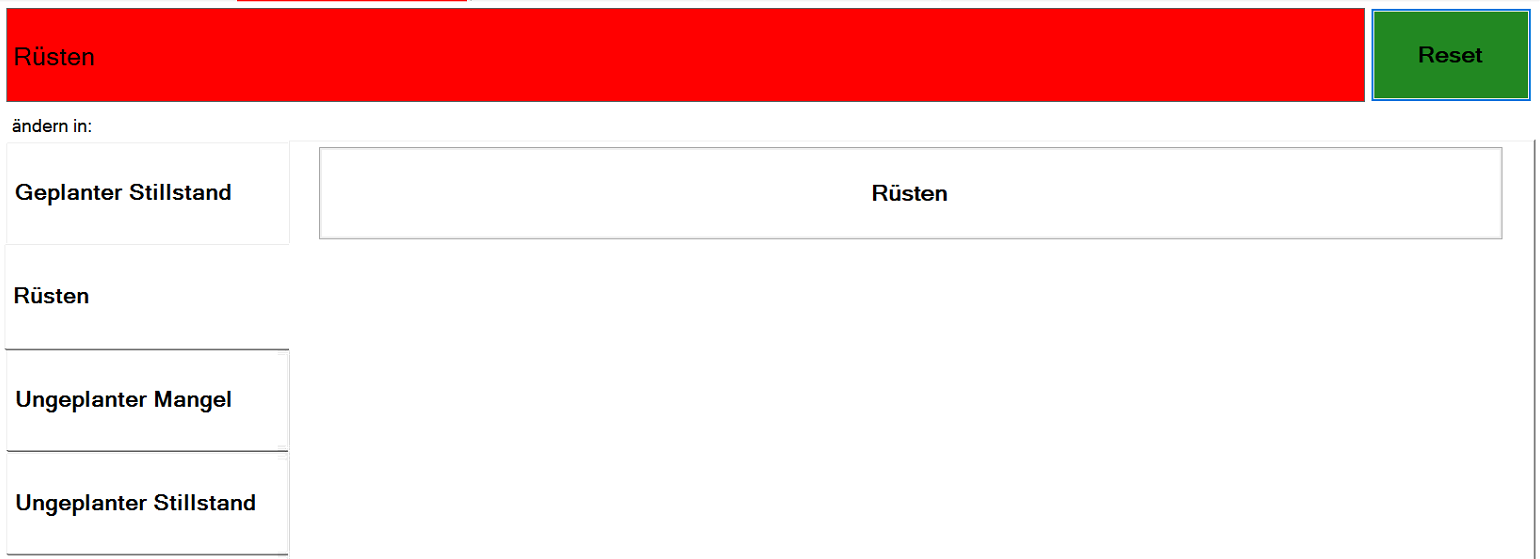

Setup

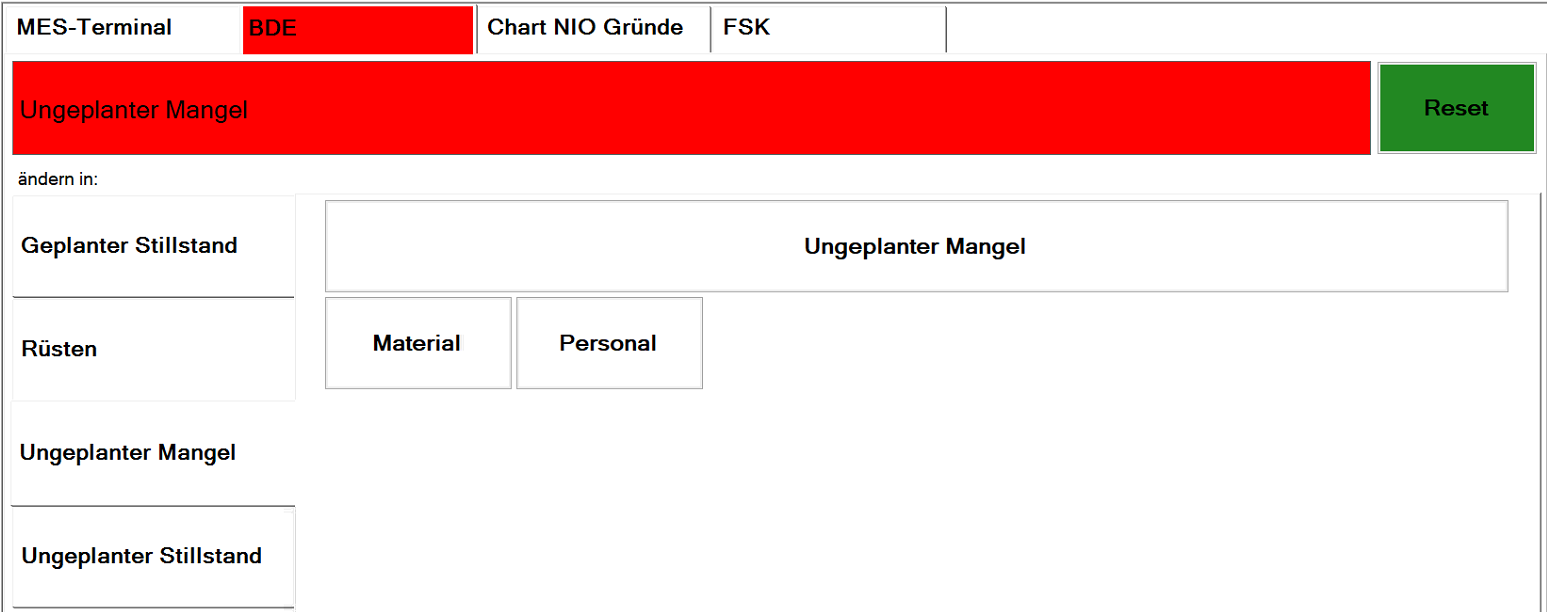

Unplanned shortage

Under the category Unplanned shortage define if the plant is not ready for production just because of missing material or missing personnel.

Unplanned Downtime

Under the Unscheduled downtime tab, the following technical causes can be defined for why the plant is currently unable to produce as scheduled:

- Mechanical: There is a mechanical malfunction at the plant.

- Electrical: There is an electrical fault at the plant.

- Q-Problem: The components produced by the plant are of insufficient quality for reasons that are not yet clear.

- Cleaning: The plant needs unscheduled cleaning.

- Fault MES terminal: There are problems at the MES terminal which prevent production (e.g. labels cannot be printed).