(remove this paragraph once the translation is finished)

MES-Terminal

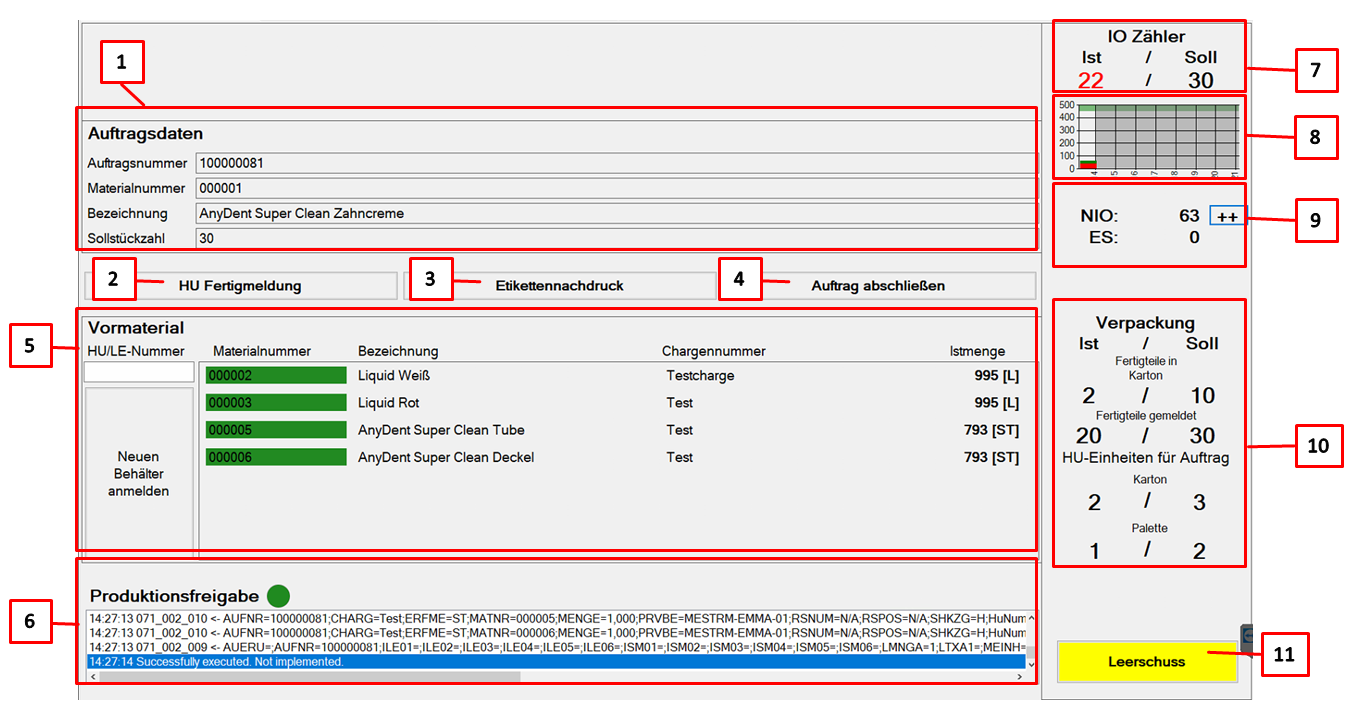

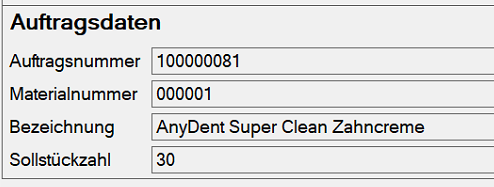

The MES-Terminal is the main interface for processing orders. In the figure below, an order is already in progress. As long as no order has been set up, the Start button is located above the order data, which can be used to set up the next order. The elements of the menu interface are explained below.

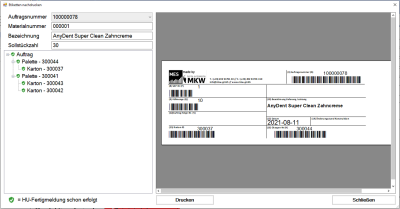

- HU completion notification: Using this button, the current HU of the smallest category can be reported as finished (see Beispiel 1). For a category 1 HU, the number of products contained can be adjusted. Following the completion message, a label is generated for labeling this HU.

- Close order: This button terminates the current order, regardless of the actual processing status. Labels are created for the packaging units which are processed at this time. An order must also be manually closed by this button after regular completion.

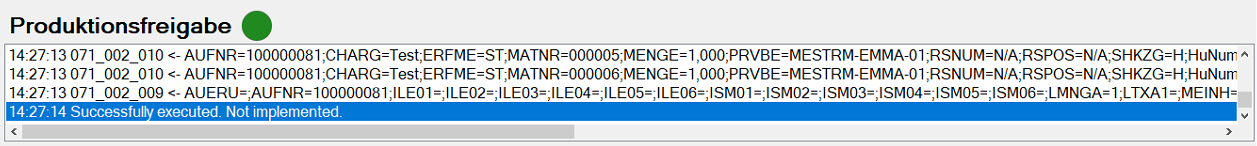

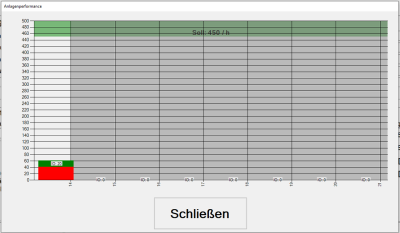

Only the required number of pieces plus an operator-specific overproduction quantity can be produced for each order. Subsequently, the production approval is withdrawn from the plant.

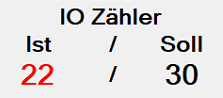

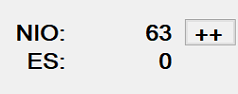

- Display NOK parts and empty shots: Here NOK the NOK parts accumulated for this job are counted. With the ++ button, OK parts can be rewritten to NOK parts by the operator. The number of NOK parts is increased by 1 per operation while the OK counter is reduced by 1. Only as many NOK parts can be rewritten as OK parts have been produced.

The number of empty shots for the current order is counted in the ES section.

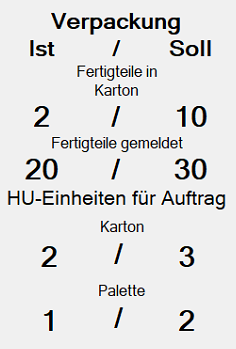

- Packaging: Here you will find the counters of the different packaging units. The division and grading of the packaging units is product-specific and varies accordingly to the order. The counters of the example shown are explained below.

- Parts in carton: Here, the OK parts are counted in the smallest packaging unit (here carton) that is currently filled. With the change to the next packaging unit, i.e. packaging unit is full, the counter resets.

- Parts reported: Counter of parts packed and labeled.

- Carton: Counter of finished and labeled cartons.

- Pallet: Counter of finished and labeled next larger (here also the largest) packing unit. In this case, two cartons can be placed on each pallet.

The manual declaration of NOK components has no influence on the finished parts and packaging units reported under Packaging. If NOK parts are declared, these are first deducted from the current HU to be filled (here finished parts in carton). Additional NOK parts, which exceed the current HU, have no influence on the counters shown under Packaging. If more NOK parts are declared than there are parts in the current HU, the Parts in carton counter does not continue to count until the actual number of OK parts exceeds the reported finished parts. The MES-Terminal therefore assumes that the packaging units that have already been filled and labeled accordingly are first refilled with the new parts.

- Empty shot: This button is required for plants which do not automatically report the material consumption correctly for an empty shot or the empty shot itself. In this case, this function must be activated manually before an empty shot is made in the plant. As long as this function is active, the button is highlighted in yellow and each production cycle is counted as an empty shot.

Examples and explanations

Example 1

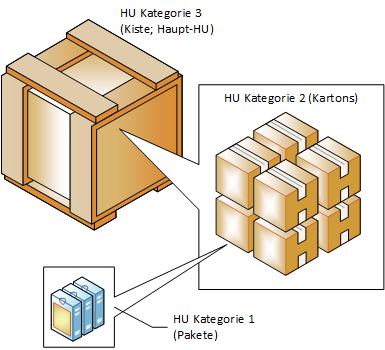

Packing units can be nested as desired. The HU of the smallest category always contains the product itself. Above this, theoretically, there can be different number of categories into which packaging units of the next smaller category are packed. This information is defined in the current order.

If there is an unfinished HU of the smallest category, this HU will be declared as completed first at the HU completed button. If the production is stopped the next HU complete message would declare the HU of category 2 completed (otherwise the filling of the next HU of category 1 is started automatically). At each subsequent HU completed message, the next higher category HU is then reported as completed until finally the main HU (HU of the highest category) is reported as completed.

If the current main HU is reported as completed during ongoing production (an HU of category 1 is filled), the button early main HU completion message can be used.

LLL

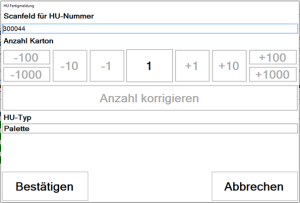

back to HU Fertigmeldung