(remove this paragraph once the translation is finished)

Extras

Debug...

The Debug… menu is a developer tool for troubleshooting and is of no further relevance to the user. If no developer is on site, it may be necessary to send this data to the developer. Using the function Save data as XML the data can be exported to an XML file and sent in this way.

Test-Scale...

If a scale is connected to the MES terminal, it can be tested via this menu. The following functions are available for this purpose:

- Make connection: Establishes the connection to the scale.

- Tare: Corrects the current reading to zero.

- Read tare weight: Displays the actual measured weight.

- Zero: Defines the current measured value of the scale as zero.

- Recall weight immediately: Displays the actual measured value.

.

Language management...

PLC connectivity...

This is a tool for setters and system administrators. The controllers connected to the terminal and their connectivity (heartbeat) are displayed. In addition, the following functions are available:

- Disable heartbeat to PLC: The heartbeat from the terminal to the plant control system is switched off. For the plant it looks like the MES terminal is switched off, or terminated. The plant could now be operated autonomously without actually terminating the MES terminal.

- Bypass automatic release: Enables the adjacent function enable automatic.

- Enable Automatic: Gives the plant the release for automatic operation independent of the PDC status.

. The function enable automatic should not be used if possible. It can lead to contradictory data if the plant is actually producing while it is officially not in production. If the plant is to be operated independently of the MES terminal, it is recommended to terminate the MES terminal.

Change counting method...

In this menu the type of piece counting can be changed:

- Manual: The parts are counted manually by entering them on the MES terminal. For this purpose, every time a HU (of the smallest order) is completely filled, the function HU Fertigmeldung is used to report and label a completely filled HU.

- machine counter: Counting is done by feedback from the system control.

- Caliber: This option must be activated if a plant produces several components with one cycle, but does not run back the exact number of pieces (e.g. the plant reports back only “ Cycle successfully completed”). The quantity, which is produced with a cycle is defined with ERP connection over the ERP order, or otherwise in the MES-order-management.

- scale: If a scale is connected to the MK|workstation, the piece count can be determined via the weight.

- Light barrier: Parts can be counted via this option if a light barrier, or a comparable sensor for component counting, is directly connected to the MK|workstation. If the light barrier for component counting is connected to the system control, the Machine counter option must be selected.

The counting method can also be changed during a running job. For example, the counting method can be set to Manual if there are problems with the counting by the plant control (Machine counter).

OK/NOK-Signaltest...

This menu is used to check the light barriers connected to the MK|Workstation. As long as the menu is open, the light barriers can be triggered without affecting the real piece counter. The interruptions of the light barriers are then only counted in the counters of the menu itself.

Options...

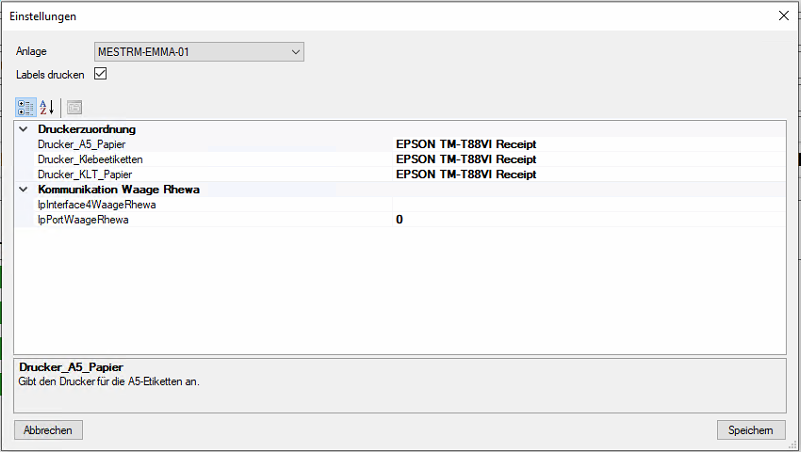

The following settings can be made in the Options menu:

- Assignment: The drop-down menu is used to select the plant that is to be assigned to the MES terminal.

- Print label: If this option is activated, labels for labeling the HUs are printed automatically during order processing.

- Printer assignment: Here a printer can be assigned to each of the different label formats.

- Communication scale: If a scale is connected, the IP address and the port of the relevant scale must be entered here.